Advanced finishing methods: enhancing the worth of your prints in 2025

By 2025, print finishing has transformed the value, attractiveness, and durability of printed goods, making it more than just an add-on. Advanced finishing techniques have become crucial for differentiating out in a competitive market, as businesses and consumers expect prints that are of superior quality, long-lasting, and visually attractive.

Modern finishing techniques offer countless opportunities to improve the tactile and visual experience of prints, from spot UV treatments and opulent foil stamping to precise laser cutting and environmentally friendly decorations. These developments address typical issues including print durability, branding impact, and affordable customisation in addition to adding a high-end touch.

Using the newest finishing technologies will help you fulfill consumer expectations, boost brand value, and increase engagement, whether you're a print service provider or a company trying to leave a lasting impression. Discover how innovative print finishing techniques may turn routine printouts into stunning artwork.

The Importance of Advanced Finishing in 2025

The print market is more competitive than ever in 2025, and companies and brands are looking for methods to set their products apart from the competition. Advanced finishing processes have become crucial tools in this context to improve printed materials' tactile feel and visual appeal, giving them a clear competitive advantage.

Consumers today want more than merely useful prints; they want high-end, long-lasting, and eye-catching items that make an impression. Prints with superior finishes can improve a brand's image, provide value, and leave a lasting impression whether they are used for packaging, marketing materials, or business collateral.

In addition to changing the way prints feel and look, advanced finishing increases their longevity and makes sure they stand out in busy areas. The luxury, texture, and distinctive features that consumers seek are provided by methods like die-cutting, digital foil stamping, UV coatings, and soft-touch laminations, which assist companies in meeting their standards for excellence and originality.

These finishing techniques are becoming more widely available, affordable, and adaptable as technology advances, enabling companies of all sizes to produce outstanding prints more quickly without sacrificing quality. To put it briefly, in today's fast-paced, image-driven world, superior finishing is no longer a luxury but rather a need to remain competitive and current.

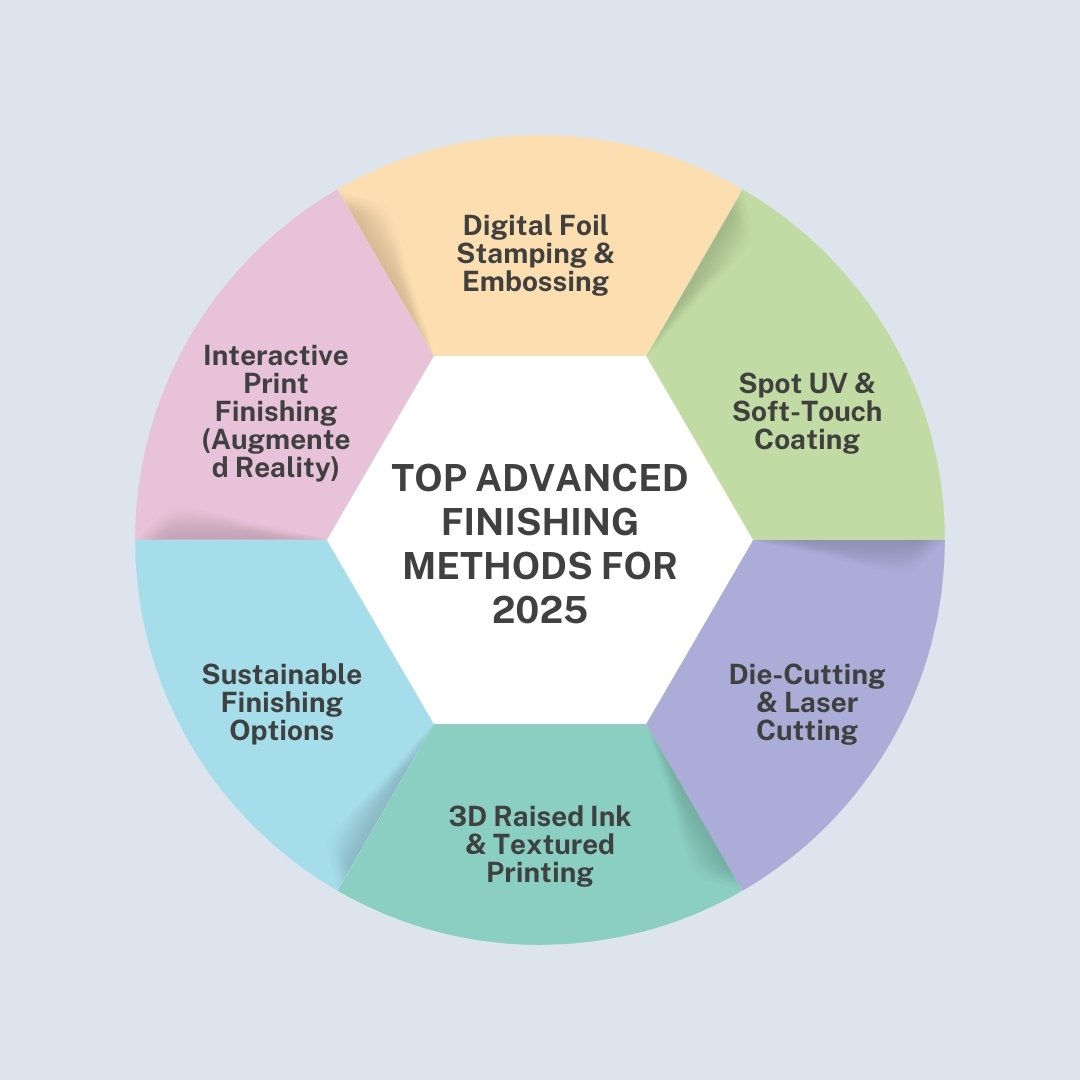

Top Advanced Finishing Methods for 2025

Print finishing is still developing as 2025 draws near, providing new and creative ways to improve the appearance and robustness of printed goods.

Here are some of the top advanced finishing methods that are expected to dominate the print industry this year:

- Digital Foil Stamping & Embossing

- Spot UV & Soft-Touch Coating

- Die-Cutting & Laser Cutting

- 3D Raised Ink & Textured Printing

- Sustainable Finishing Options

- Interactive Print Finishing (Augmented Reality)

1) Digital Foil Stamping & Embossing

The finest of both worlds—luxurious metallic foils with finely detailed designs—are combined in digital foil stamping and embossing. High-end finishes are possible with these techniques without the costly setup fees associated with conventional foil stamping.

- Applications: Business cards, luxury packaging, high-end brochures, and invitations.

- Benefits: Fast, cost-effective, and capable of producing stunning results with minimal waste.

2) Spot UV & Soft-Touch Coating

Spot UV is ideal for giving some parts of your print high-gloss finishes, which will stand out against matte backgrounds. The tactile sensation is improved by the smooth, velvety texture that soft-touch coatings offer.

- Applications: Brochures, high-end magazines, invitations, and packaging.

- Benefits: Enhanced visual impact, premium feel, and increased durability. Spot UV also adds depth to designs, making them more engaging.

3) Die-Cutting & Laser Cutting

Prints stand out thanks to the complex cuts and unique shapes made possible by die-cutting and laser cutting. These approaches are perfect for making distinctive, unforgettable designs that aren't achievable with conventional cutting procedures.

- Applications: Custom packaging, business cards, greeting cards, and promotional materials.

- Benefits: Highly creative, precise, and customizable—perfect for differentiating your brand. Laser cutting offers fine detail, making designs pop.

4) 3D Raised Ink & Textured Printing

The raised, tactile effect created by 3D raised ink printing encourages the user to touch and feel the pattern. By adding dimension and texture, this creative method makes designs come to life and improves audience engagement.

- Applications: Invitations, certificates, high-end brochures, and luxury packaging.

- Benefits: Unique, memorable, and sensory—perfect for making a lasting impression. Raised ink also makes prints more accessible, especially in braille formats.

5) Sustainable Finishing Options

Environmentally friendly finishing alternatives are essential as concerns about sustainability rise. As companies seek to lessen their environmental effect while maintaining premium finishes, water-based coatings, biodegradable foils, and recyclable papers are becoming more and more popular.

- Applications: Any print material looking to highlight eco-conscious branding, such as packaging, promotional materials, and corporate stationery.

- Benefits: Aligns with sustainability goals while maintaining premium quality. Eco-friendly finishes are becoming increasingly popular among consumers who prioritize green choices.

6) Interactive Print Finishing (Augmented Reality)

A developing trend in print is augmented reality (AR), which provides users with interactive experiences. By integrating augmented reality (AR) into finishing procedures, consumers may use their smartphones to scan prints and access extra content, animations, or product details.

- Applications: Marketing campaigns, event invitations, packaging, and catalogs.

- Benefits: Offers a futuristic, engaging experience that adds an extra layer of value to printed materials.

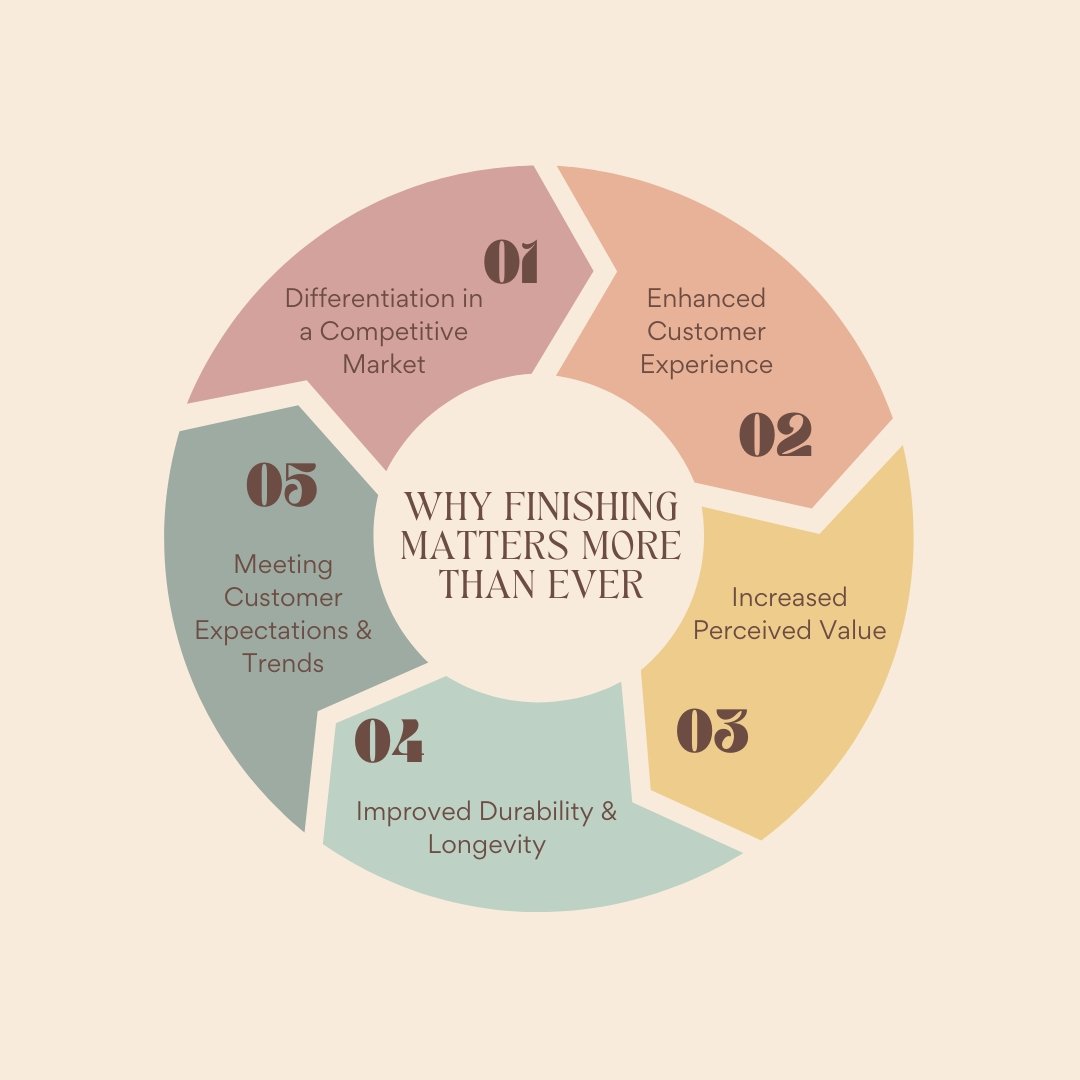

Why Finishing Matters More Than Ever

Physical prints are valuable because they may leave a lasting, tactile impact at a time when digital content is king. Customers now demand superior finishes that improve the appearance and feel of printed goods, so a simple printed piece is no longer sufficient to draw attention.

Here’s why finishing is more important than ever in 2025:

- Differentiation in a Competitive Market

- Enhanced Customer Experience

- Increased Perceived Value

- Improved Durability & Longevity

- Meeting Customer Expectations & Trends

1) Differentiation in a Competitive Market

Making an impression is essential for companies that use print for branding, packaging, and marketing. Printed materials stand out from the competition because to sophisticated finishing techniques including foil stamping, soft-touch coatings, and embossing.

2) Enhanced Customer Experience

Designs that are tactile and aesthetically pleasing attract to consumers. Prints become more captivating and memorable when finishing techniques like spot UV, textured printing, and die-cutting are used to give depth and character. A well-made product encourages consumers to interact with the brand through touch and feel.

3) Increased Perceived Value

With the correct finishing, a basic print can be turned into a high-end item. Expensive finishes convey exclusivity and quality, increasing the likelihood that consumers will connect the brand with excellence and professionalism. This is particularly crucial for sectors like high-end marketing materials, invites, and luxury packaging.

4) Improved Durability & Longevity

In addition to being aesthetically pleasing, finishing shields prints from deterioration. Water-resistant treatments, UV coatings, and laminations increase longevity and guarantee that prints hold up well over time. This is especially crucial for objects that be handled often, such as menus, brochures, and business cards.

5) Meeting Customer Expectations & Trends

Consumers of today demand sustainability, innovation, and originality from brands in all its forms, including printed materials. Water-based varnishes, recyclable foils, and eco-friendly coatings enable companies to satisfy these demands without sacrificing quality.

Final Thought: Elevate Your Prints with Advanced Finishing

By 2025, sophisticated finishing techniques are not merely improvements; they are necessary to distinguish prints, boost their longevity, and leave a lasting impression. Investing in superior finishing processes can greatly increase the value and appeal of your prints, regardless of whether you're in marketing, packaging, or commercial printing.

Visit CutnBind.com to learn more about our selection of cutting-edge finishing options if you want to elevate your print output. Allow us to assist you in producing prints that are memorable!